Coffee processing

The challenge

Drying fresh-picked coffee beans to 11% moisture quickly and efficiently, without taint, mould or off flavours.

The solution

Modular SVPro coffee drying solutions - scaled to operation, extendable and efficient. Can be integrated into existing drying, or stand-alone and free to run.

Smarter processing

"Some innovative grain drying methods... have been introduced into coffee drying facilities in the last few years in an effort to increase the drying capacity and the energy efficiency of conventional coffee drying installations, and at the same time to maintain high coffee quality. From the results, the dried coffee beans were considered of excellent quality" - New technologies for drying coffee (de Sousa, Roberto)

"the solar dryer of coffee with the largest natural ventilation area... is the most energy efficient and the most appropriate to preserve the quality of coffee" - Post-harvest installation and a solar dryer of coffee (Campina Grande)

Drying of freshly harvested cherry coffee

Coffee growing along Australia's east coast is a burgeoning industry, with current estimates of four to five times the 1000 tonne production levels recorded in 2011. Growing as it is, the Australian industry is still a very small contributor to the annual production of ten million tonnes worldwide.

SVPro solutions are available for both dry processing, as used in the majority of countries exporting coffee, and for those more affluent countries, like Australia, that typically utilise wet processing.

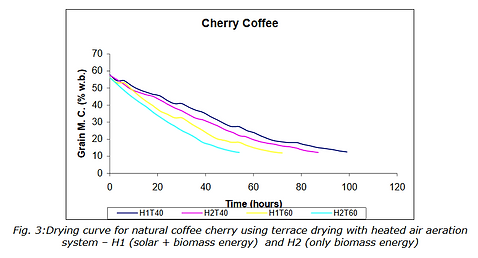

Cherry coffee as harvested has a typical moisture content of around 57%, most of which is in the outer, fleshy pulp. Within hours of harvest the pulp needs to be treated - either solar dried (dry method); or immersed, the pulp removed, and then dried.

The finished moisture content of the dried green beans, ready for roasting, is typically 11%, with the moisture content needing to be removed after initial pulp processing of up to 45%.

SVPro solutions can be applied to both wet and dry processing methods; system size, scaling and suitability for climatic conditions are key parameters of the design.

SVPro solutions comprise modular solar collectors, which dehumidify and heat the ambient air, and fan and air distribution arrays to deliver the dried and preheated air to the coffee. Air flow rates, temperatures, relative humidity, and the desired time to complete processing all govern system design, as do a number of other factors. Additional options include temperature and humidity controllers, zone monitors, flow control and check valves, each of which must be matched to the system.